Problem overview

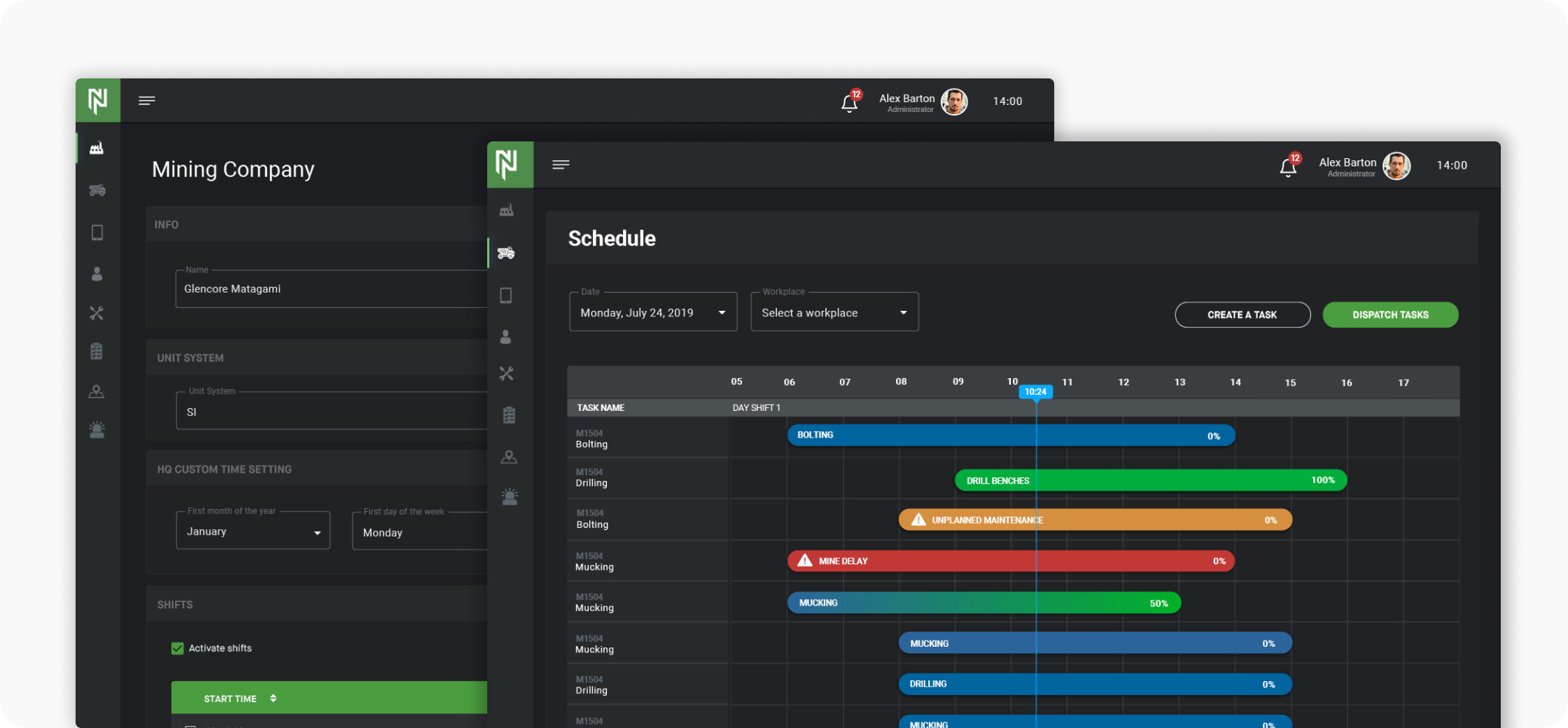

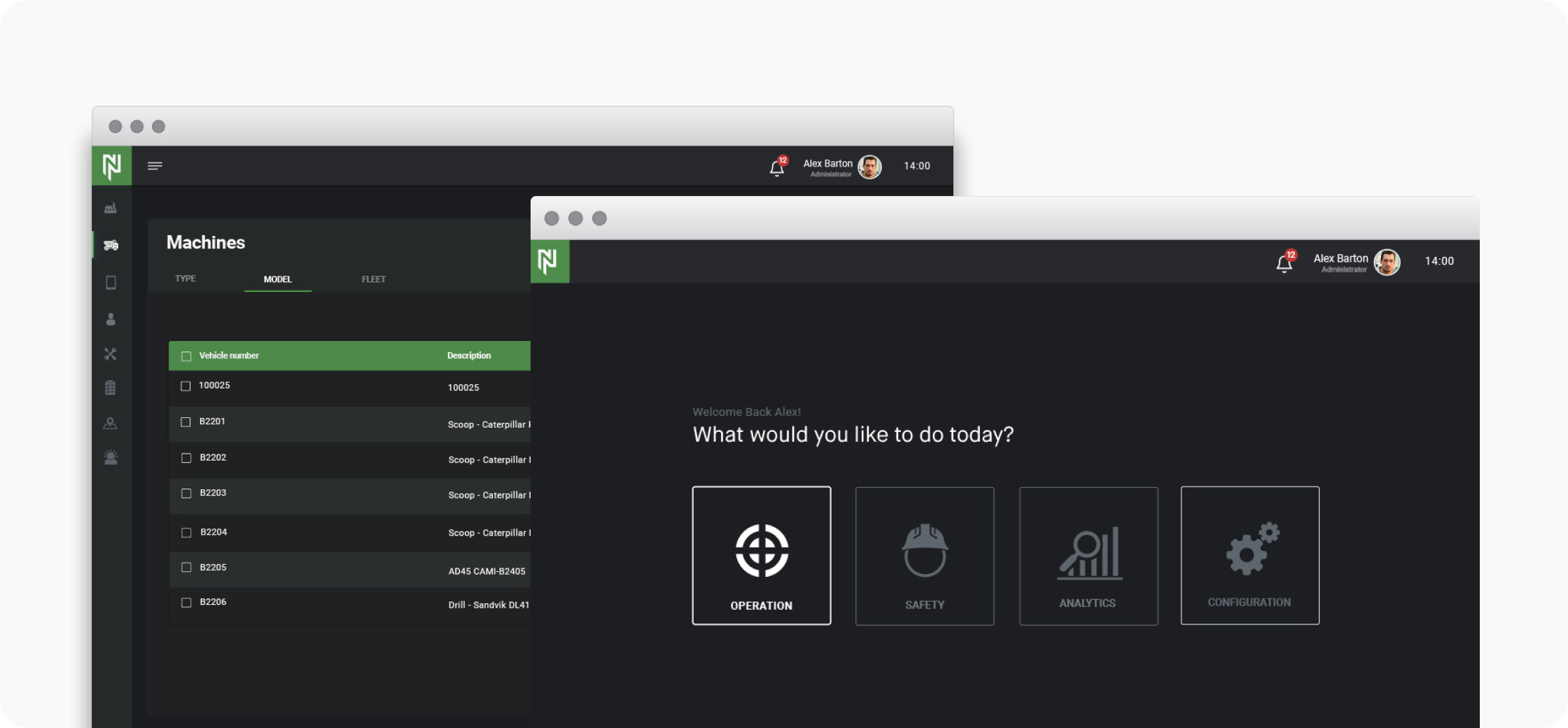

There was a profound usability issue with the legacy platform that the majority of current users today have hard time using. The learning curve and lack of documentation ressources make it difficult for the mine operators to adopt the software and they stop using it out of frustration. Also, users today also prefer a more modern web based platform as they can utilize it's tools no matter where they find themselves and on various devices. While competitors are working on increasing usability and user experience in their software offerings, Newtrax has fallen behing for several years. In order to improve user/client relationships, a complete digital transofrmation of the lgeacy platform was needed, based on a next generation web software technologies and user-centric methodologies.

Who are the users?: The primary users are the mine operators that work daily above ground in the control room. These are the users that will use the tools to monitor efficiency, productivity, machine health and miner safety underground.

- Lack of safety tools and features

- Inability to track work progress

- Requires installation on desktop

- Hard to use and understand

Success Metrics

Advancing hard rock mining technology in designing a next generation enterprise platform with the best data sets to train AI and to allow for greater tracking of machines productivity and miner saftey.

- Increase mine productivity The OEM-agnostic OptiMine fleet management system enables you to optimize the three dimensions of your fleet Overall Equipment Effectiveness (OEE) OEE = Availability % x Utilization % x Quality of Work %

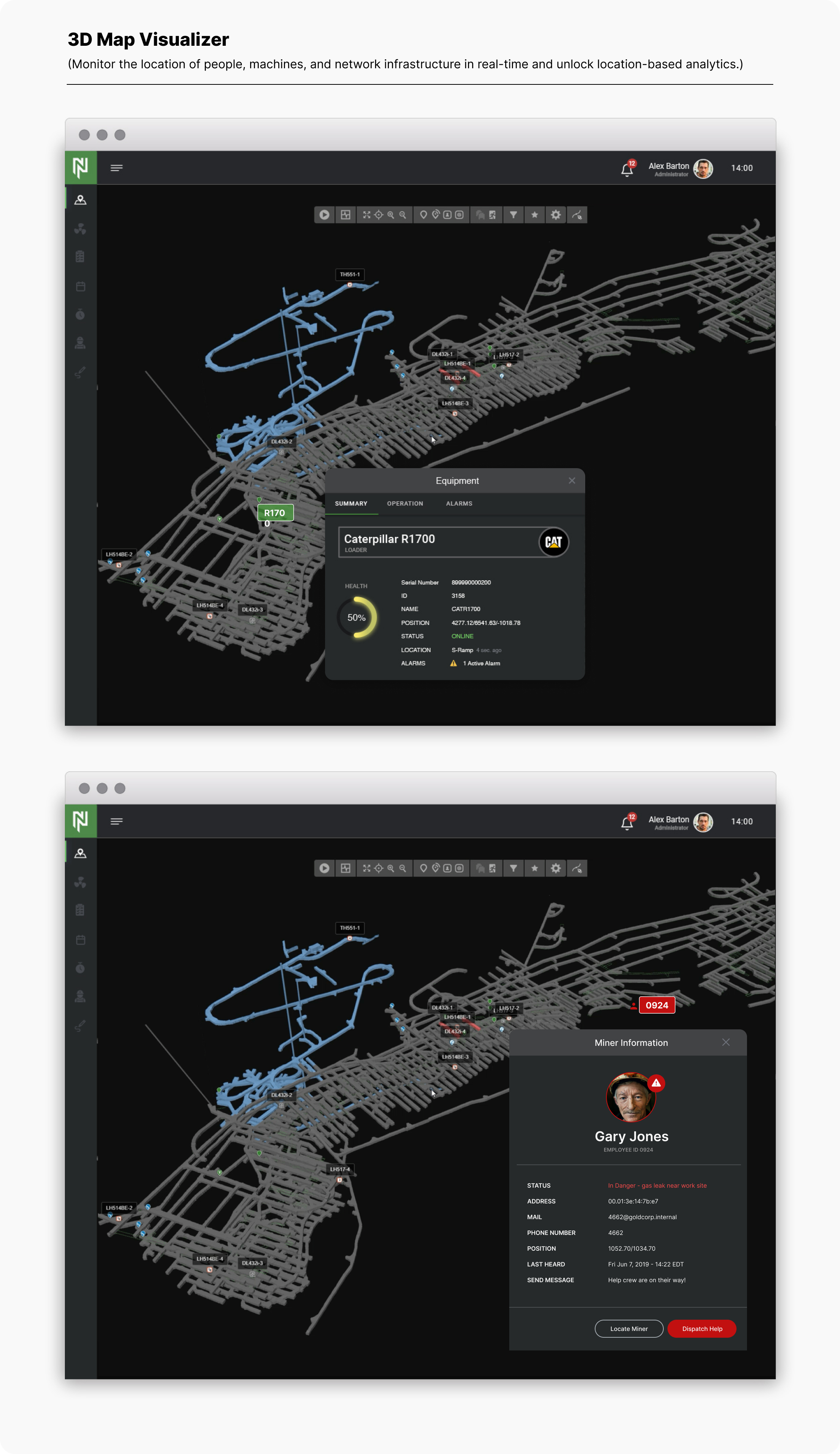

- Health, Safety & Security Empowers your workforce with the real-time information they need for optimal safety, such as the location of all equipment underground and the status of all miners.

- Greater Situational Awareness By knowing where everyone is and where machines are underground, there is a reduction of critical issues such as collisions and unepected events.

- Revenue Growth By reducing cost of operations and reducing staff injuries, there increased productivity ultimately affecting the revenue growth of the mine.

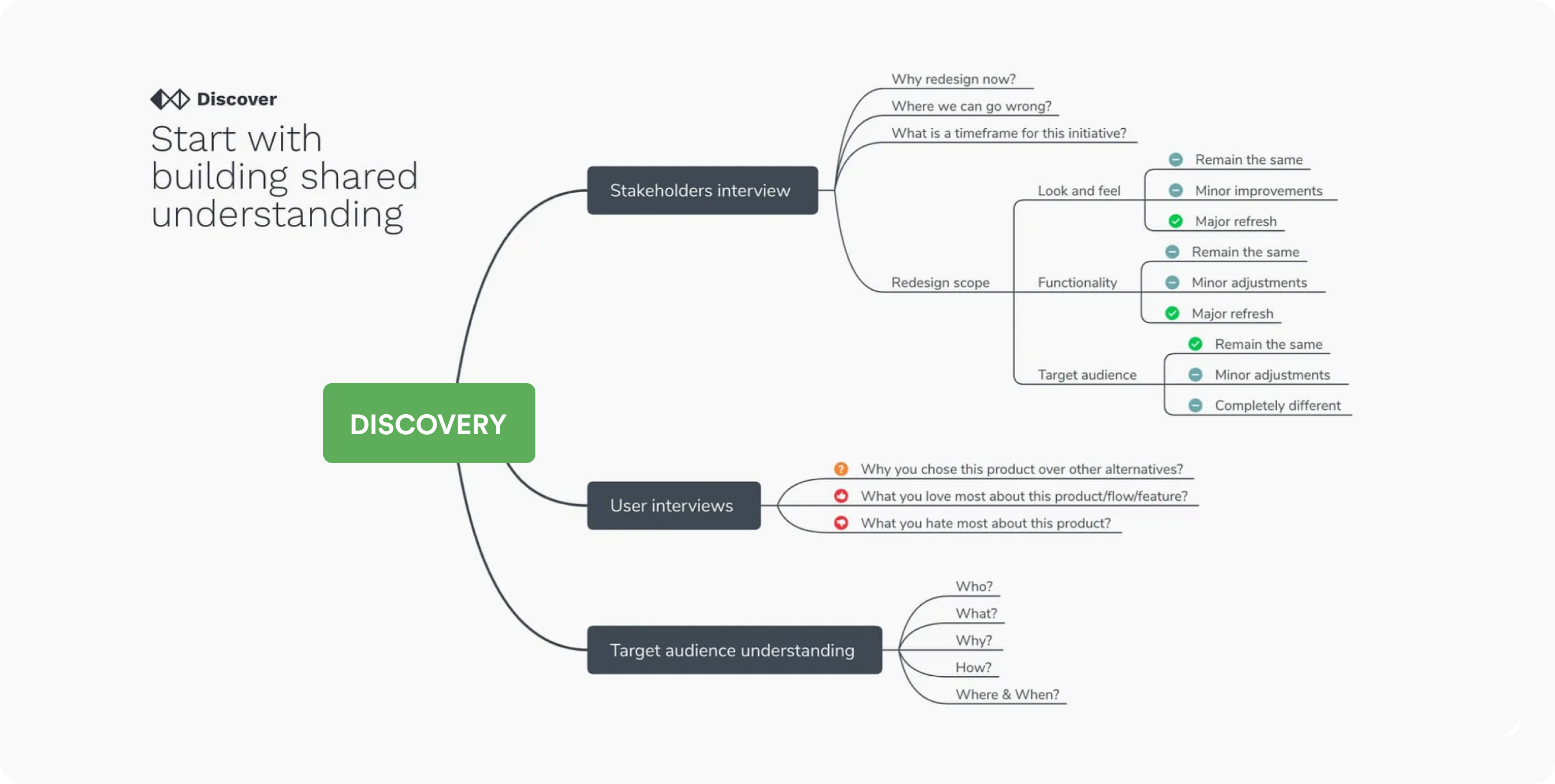

Narrowing in the problem

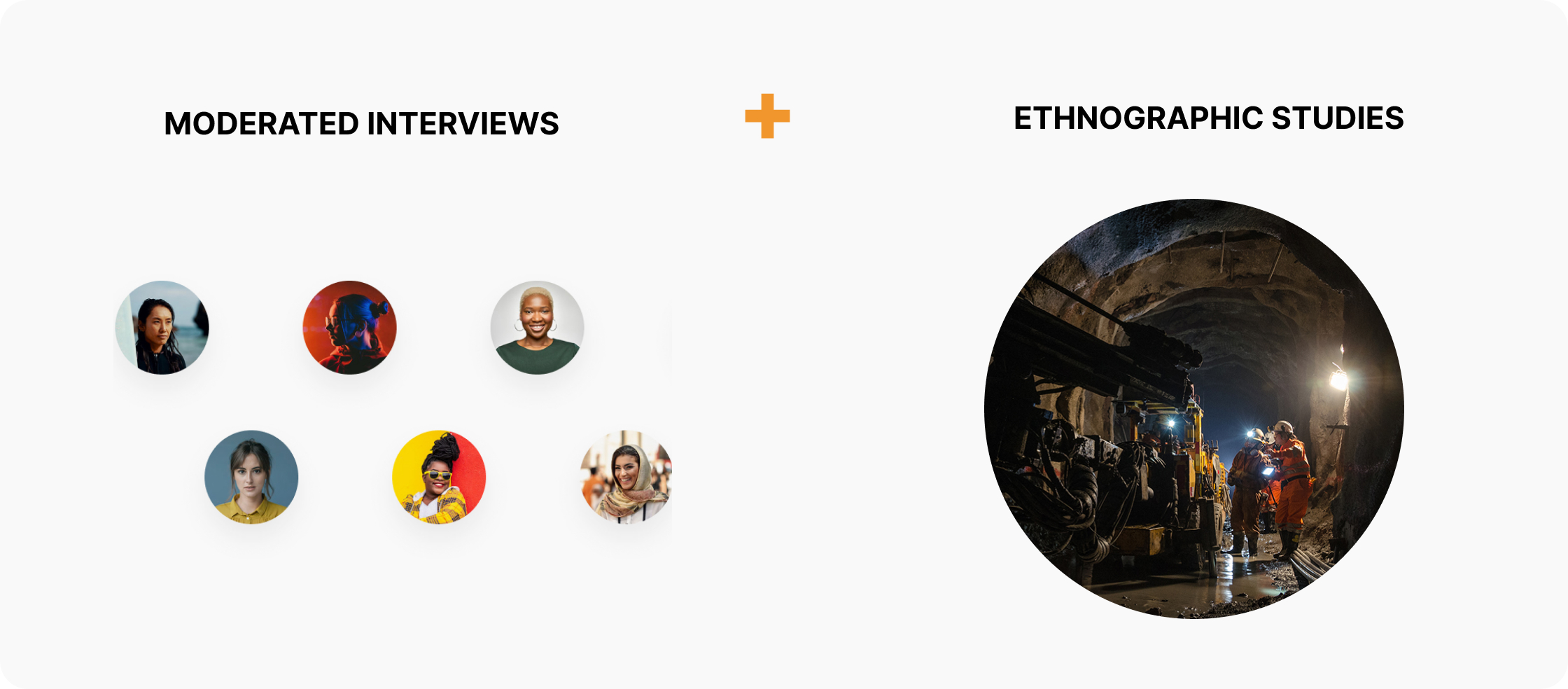

To further understand the frustrations and needs of the users, Newtrax sent me to various mines to observe and conduct ethnographic studies within the user's work enviroment. I visited mines in Brazil, the Unites States, Chile and Australia.

Moderated Interviews: I interviewed mine operators and mine managers from various countries to understand their frustrations and needs with the current product. The aim was to uncover issues causing frustration and determine how to improve their work experience and the relationship between operators, managers and miners.

Ethnographic Studies: I visted various mine sites to immerse myself in the users' real work settings, engaging with different user types such as mine managers, operators, supervisors, and miners. Spending weeks actively participating in their tasks using the legacy software, I directly experienced the frustrations users face daily. Throughout my mine visits, I gathered and analyzed field notes, later presenting these findings to the team.

Rethinking the minign safety and productivity experiences

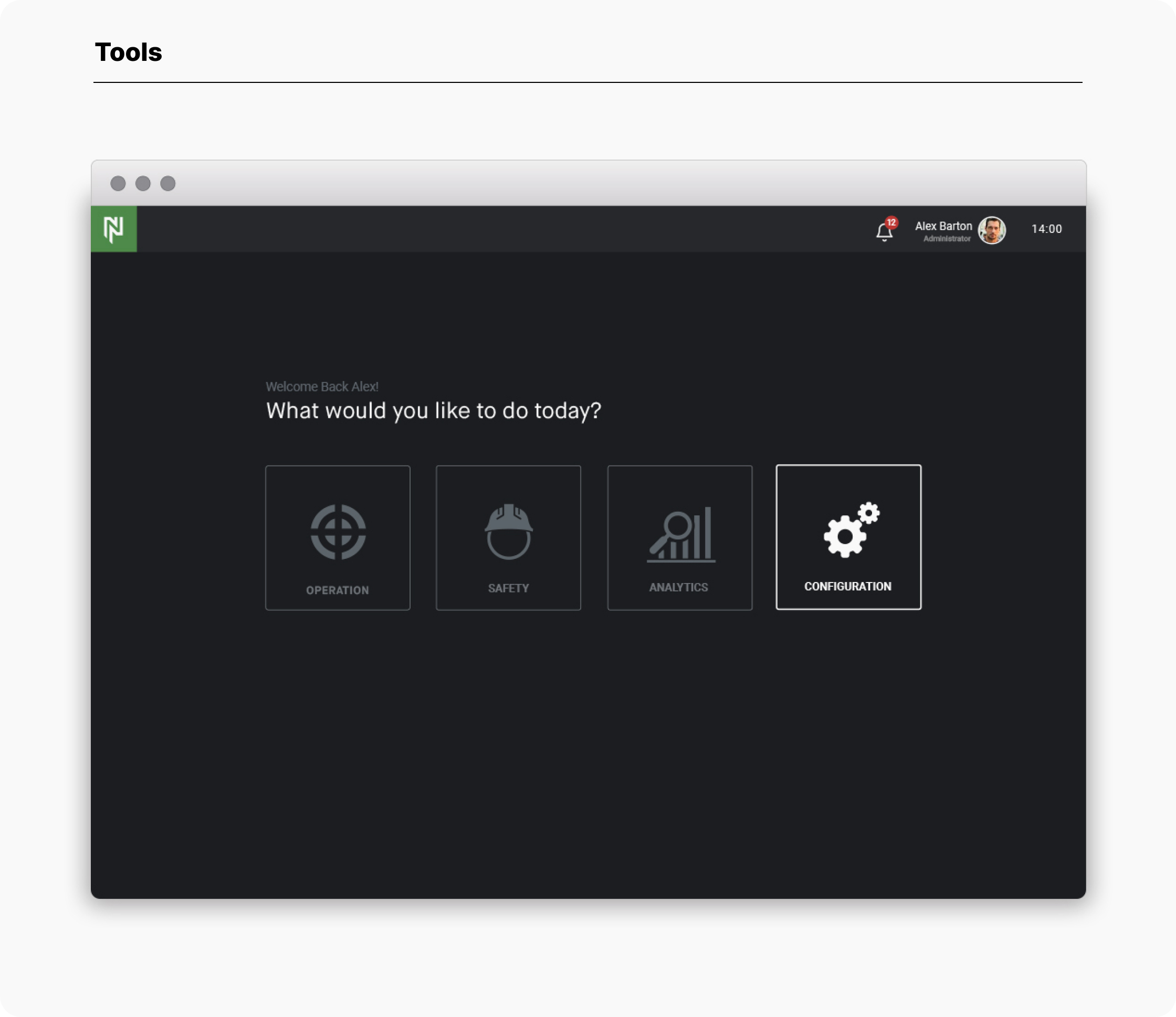

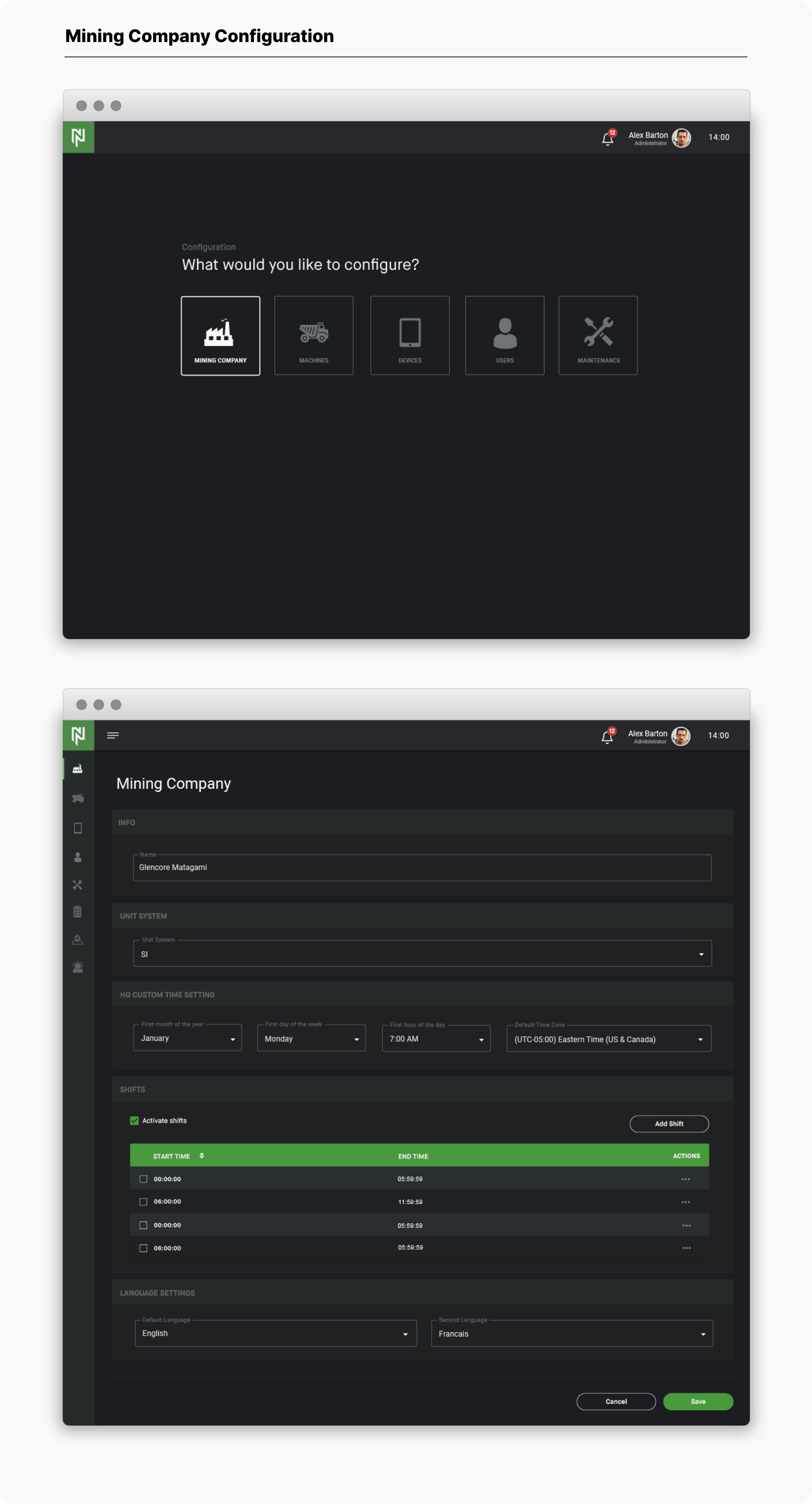

Presenting my findings to the team and stakeholders, I realized the issues stemmed from the old platform's development logic, neglecting user experience and flooding screens with information. Users, often without high education levels, struggled with data overload, particularly in South American countries. The design approach needed rethinking, especially considering that mine operators spend over 8 hours a day staring at screens, leading us to opt for a dark theme to reduce eye strain. We removed obsolete features, added modern tools, and addressed a crucial need for monitoring miners' environments with the Ventilation on Demand system. This system automates fan activation based on gas detection, improving safety and ease of use, facilitated by a mobile app for control underground.

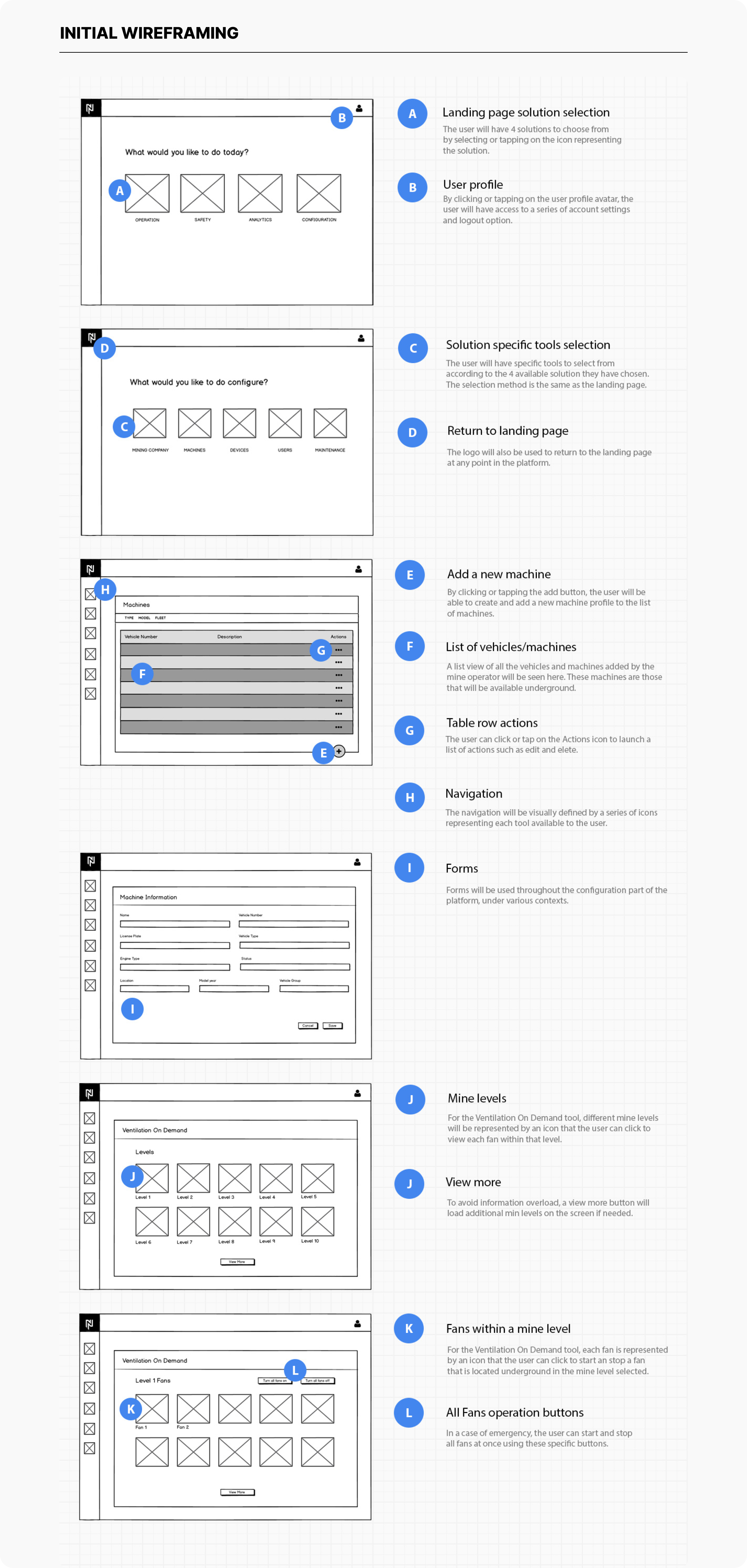

Iterative approach and design sprints

There are thousands of hard rock mine sites around the world that lack proper safety and security systems to protect their workers. Adding to this, the lack of tracking, in real time, of underground activities, it becomes obvious that there is a significant need for more cutting edge techology and software to facilitate the overall mine management.

A better experience for mine managers and operators also means bringing in safety and prevention to the underground workers. With the ability to see everything that is going on in real time underground, this is a game changer in the mining industry.