Problem Overview

On a hardware perspective, the problems were related to lamps breaking down or plastic melting due to the underground enviroment. Batteries not retaining their full charge capacity, was also an important issue. On the Personal Safety Device, the Firmware User Interface was not intuitive and didn't reflect the education levels of the various miners using it through out the world. In south America, some miners can't read, therefore that eliminates text as visual cues. I had to figure out a method of communication with the UI that worked for everyone. Accesibility was a major concern all around.

Who are the users?: The primary users are the miners and vehicle operators working underground. These iOT devices all communicate with each otehr through the Newtrax underground newtwork, WIFI and LTE.

- Inefficient communication

- Isolation and loneliness

- Lack of team cohesion

- Insuficient access to tools & resources

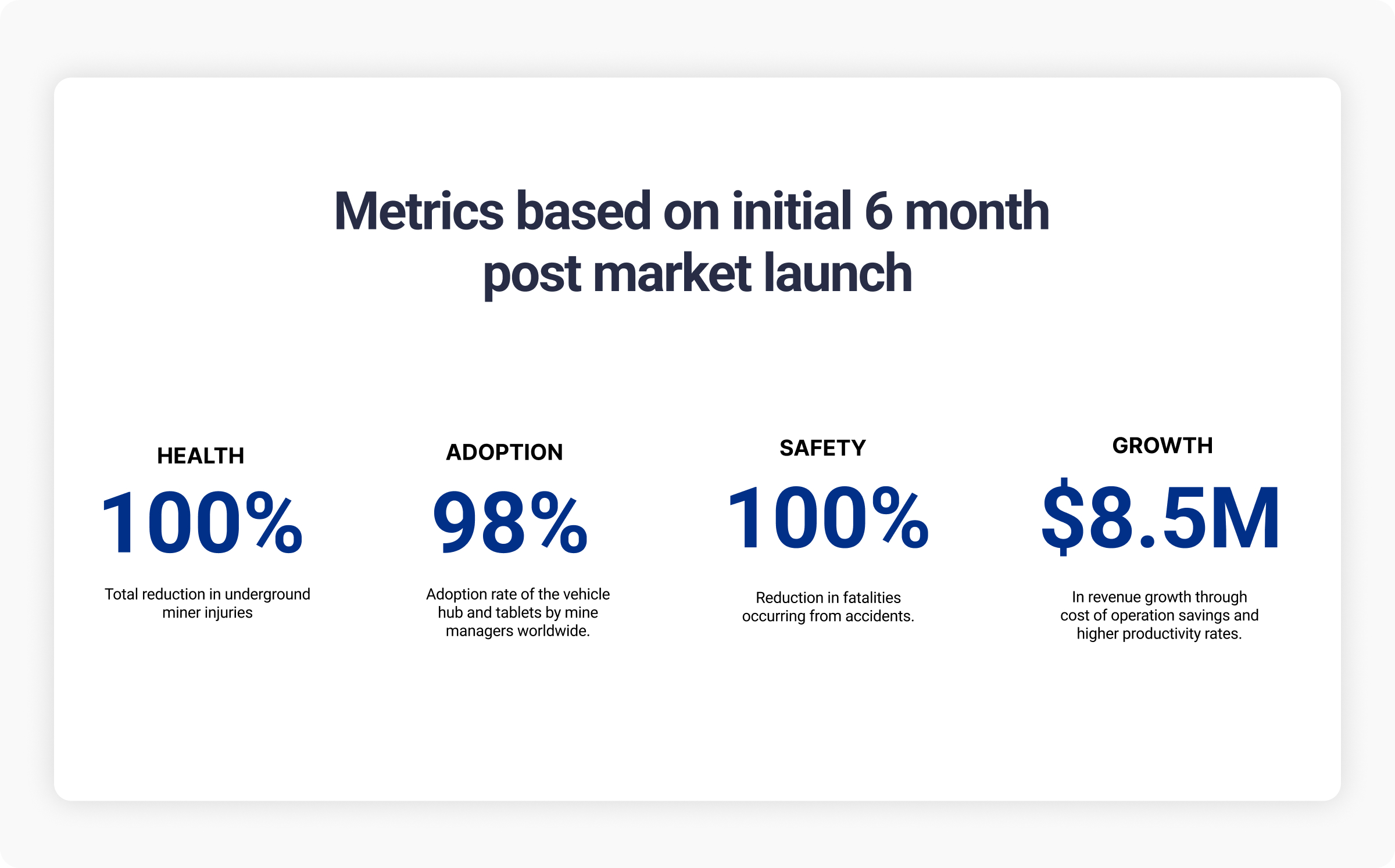

Success Metrics

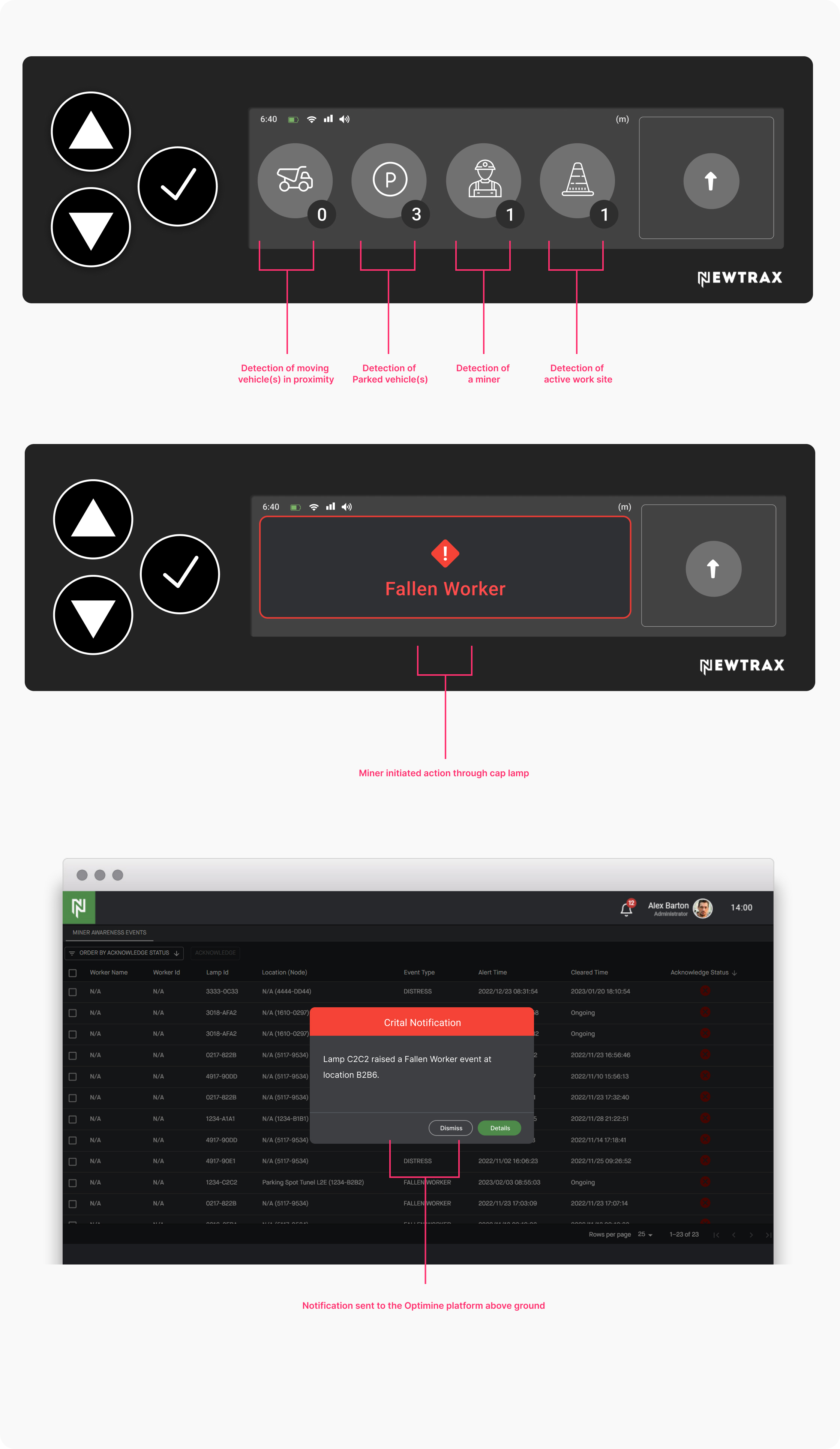

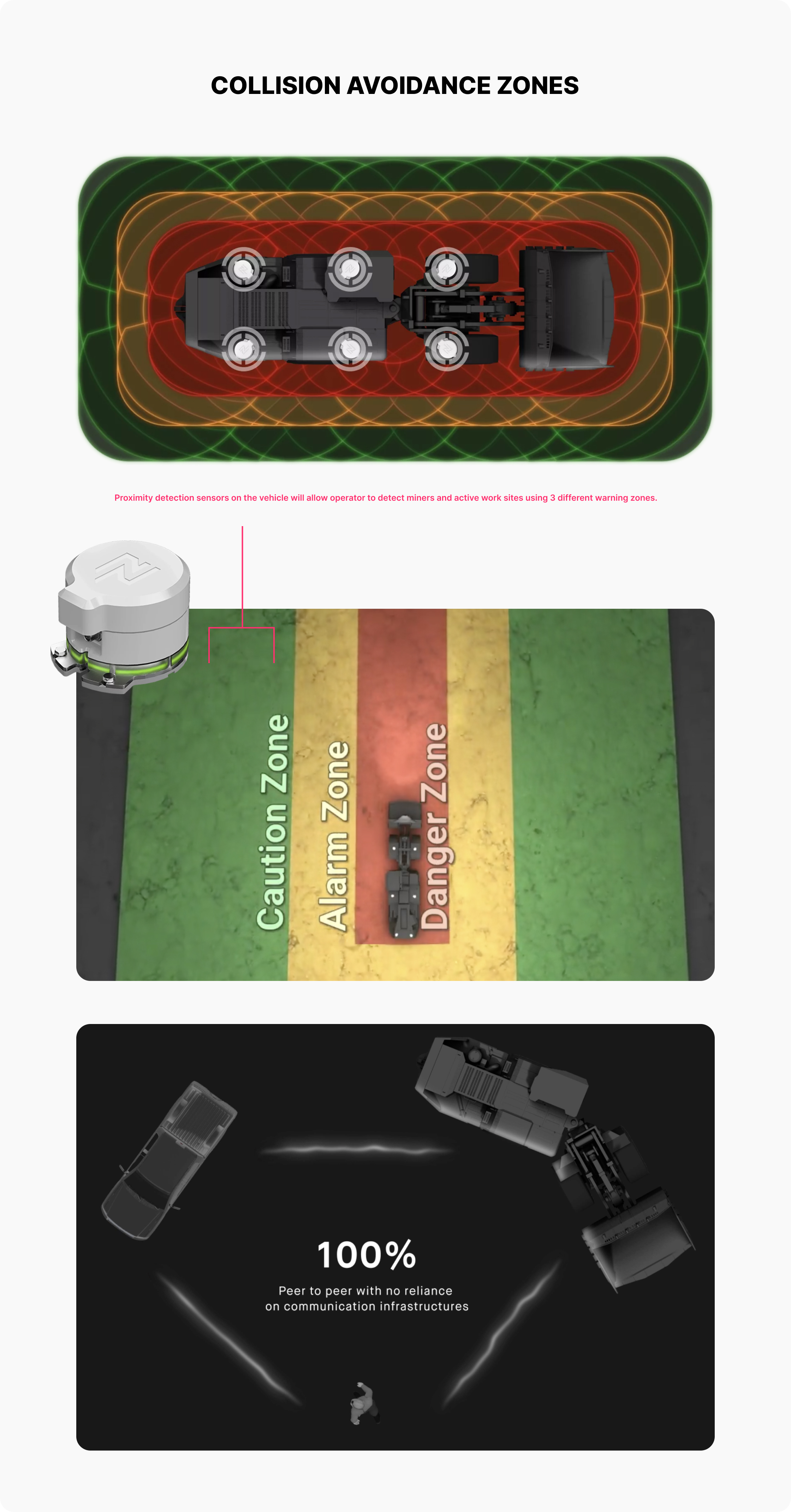

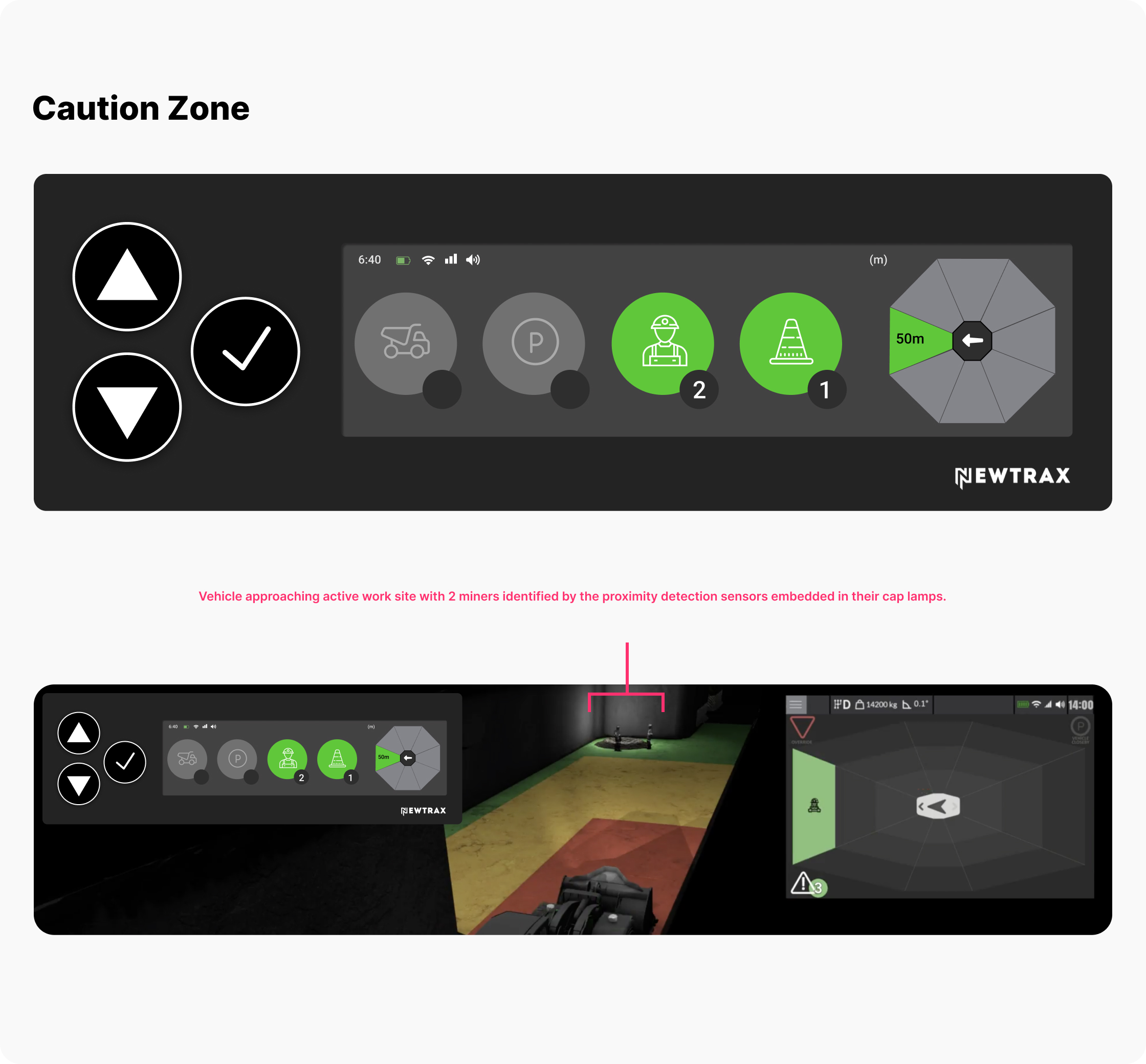

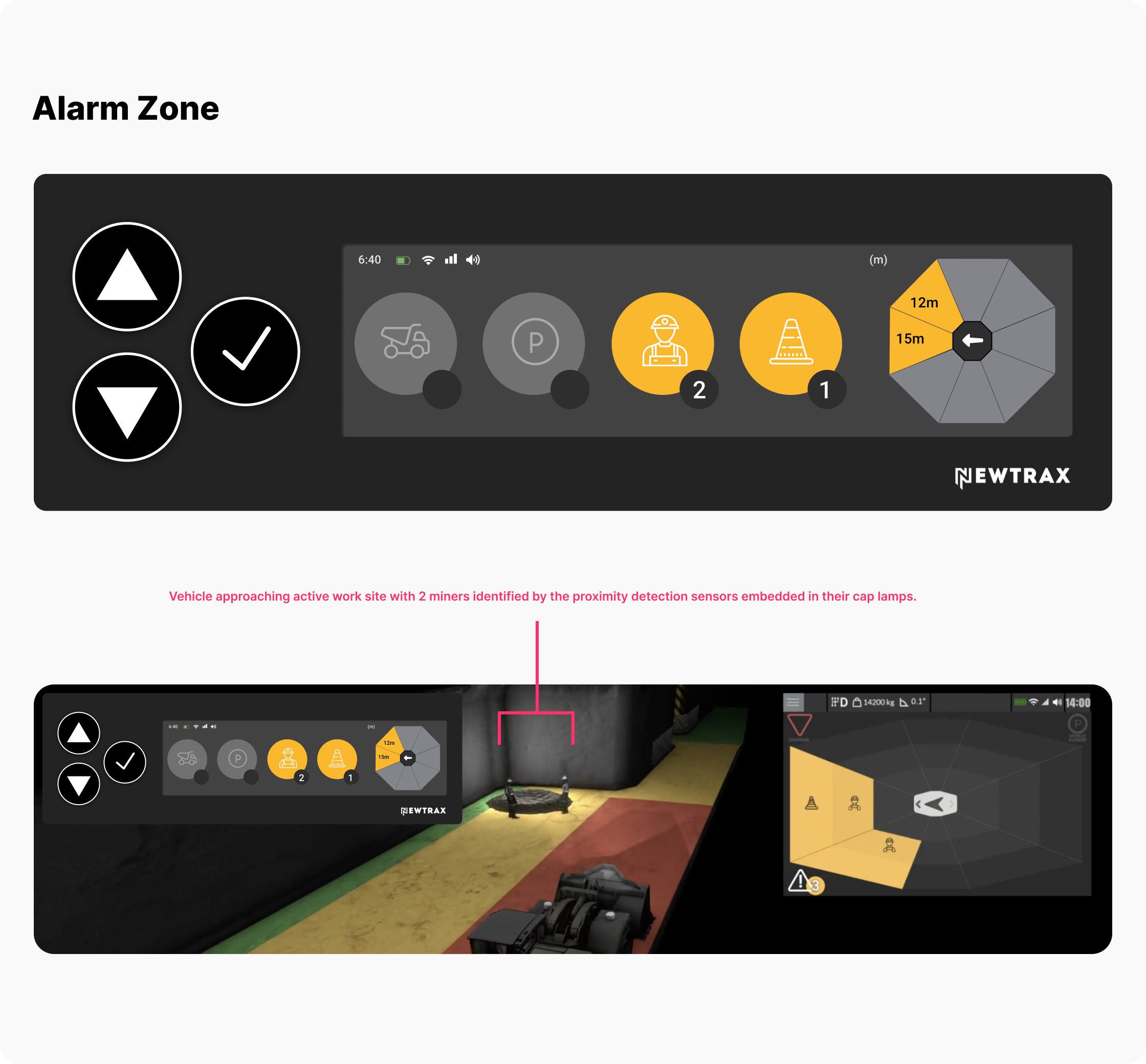

Allow miners and vehicle operators hardware and software that will allow collision prevention, proximity detection and greater overall safety underground.

- Eliminate Fatalities Increse visibility of the work area surroundings through collision avoidance systems and proximity detection. Eliminating fatalties that could occur underground.

- Dispatch help faster Faster dispatching of help during critical events. Danger alerts are shared with everyone underground inluding control center above ground.

- Tracking of machines and miners A series of emebbeded sensors detect the exact locations of a miner or vehicle within the mine.

- Revenue Growth By increasing worker safety miner productivity increases as well which ultimately impacts the growth and revenue generation of the mine operations.

Narrowing in the problem

In order to begin my design process, I needed to talk to miners from various parts of the world. I needed to understand their level of overall education and if they required accessibility features built into the device interfaces. I needed to create a color system and visual language that was going to be universal and be understood by anyone in any part of the world.

Moderated Interviews: To get a better understanding of the problem, I conducted user interviews remotely with 12 miners from various countries. Through the interviews, I wanted to discover their habits and expectations. What would make them feel more safe at work? How would it be possible to create a better communication process between miners and vehicle drivers?

Ethnographic Studies: I traveled to various countries such as Brazil, Australia, Mexico and the United States and visted various mines to immerse myself in the users' real work settings, engaging with miners and machine operators. I wanted to observe their day to day in regards to safety protocols at the front line also known as the face of the mine.

Rethinking a miner's health and safety risk management

Pedestrians working in the equipment operators' blind spots or beyond the line of sight around corners are at risk of being injured. Multiple opportunities arose to design a variety of features and experiences that would greatly improve health and safey such as accelerating an evacuation with wireless mine-wide notifications and tracking of worker's location underground.

Iterative approach and design sprints

There are thousands of hard rock mine sites around the world that lack proper safety and security systems to protect their workers. Adding to this, the lack of tracking, in real time, of underground activities, it becomes obvious that there is a significant need for more cutting edge techology and software to facilitate the overall mine management.

A better experience for mine managers and operators also means bringing in safety and prevention to the underground workers. With the ability to see everything that is going on in real time underground, this is a game changer in the mining industry.