In compliance with NDAs, confidential information is omitted. Insights are my own. Newtrax is a leading hard rock mining technology company, providing digital solutions for mining operations worldwide to improve efficiency, productivity, machine health, and miner safety.

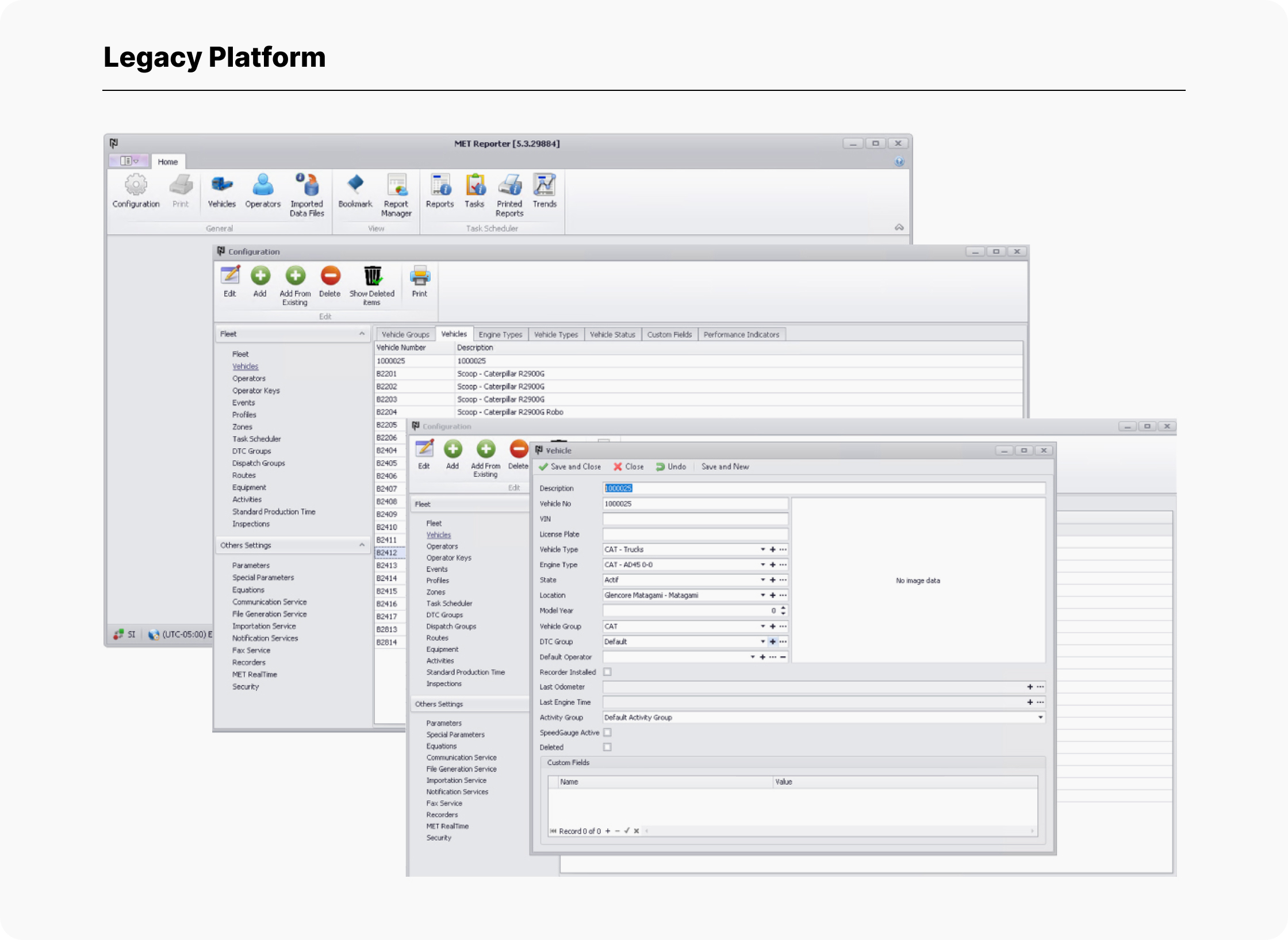

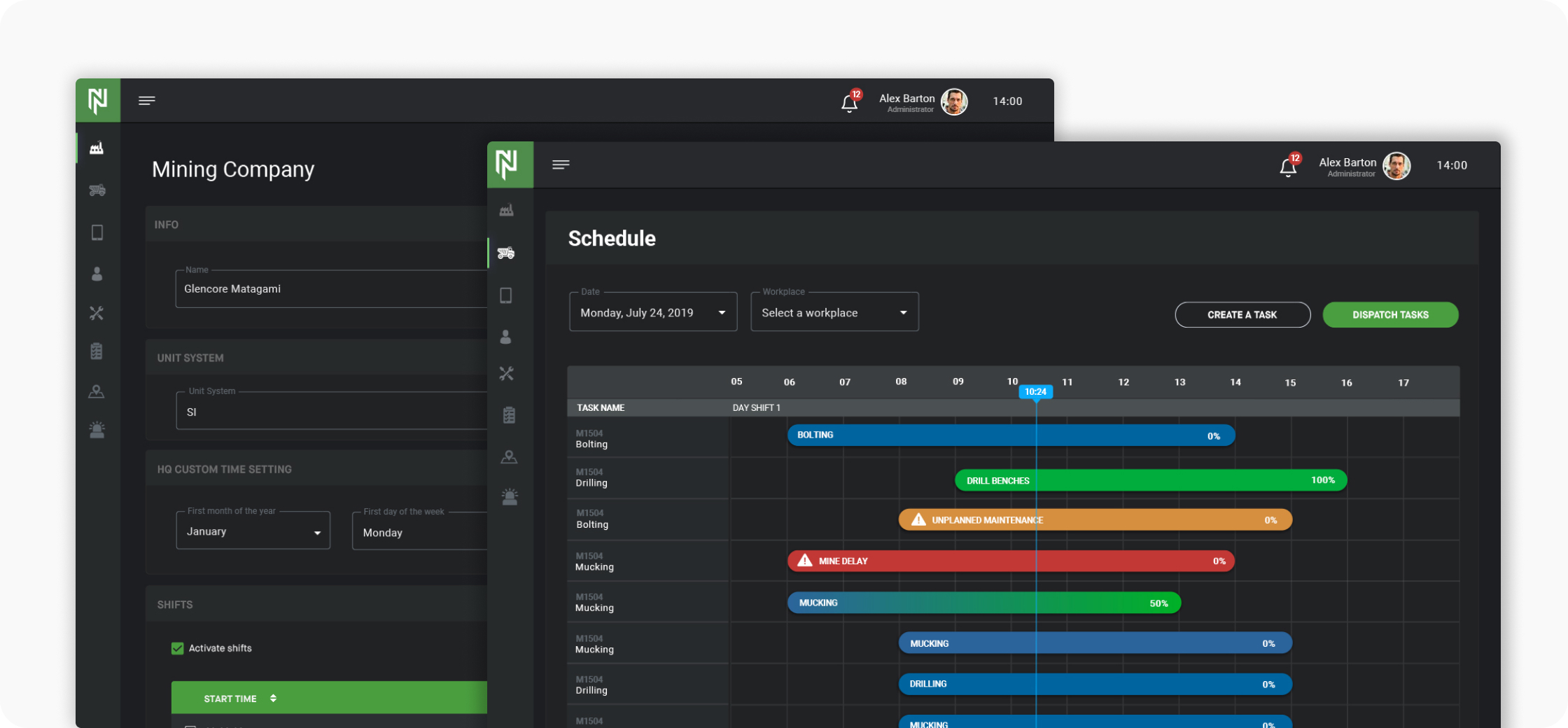

There was a profound usability issue with the legacy platform that the majority of current users had difficulty using. The learning curve and lack of documentation resources made it difficult for mine operators to adopt the software, causing them to stop using it out of frustration. While competitors were working on increasing usability and user experience in their software offerings, Newtrax had fallen behind for several years. Mine operators preferred a modern web-based platform that they could utilize from anywhere on various devices, rather than desktop-installed software that limited their access and flexibility.

The Problem:

A legacy platform for mine managers and underground miners that was difficult to use and understand. In order to improve user/client relationships, a complete digital transformation of the legacy platform was needed, based on next-generation web software technologies and user-centric methodologies.

Who are the users?

The primary users are the mine operators that work daily above ground in the control room. These are the users that will use the tools to monitor efficiency, productivity, machine health, and miner safety underground.

User Pain Points:

I owned the end-to-end experience design for Newtrax's legacy platform digital transformation—modernizing the mining operations software into a next-generation web platform using user-centric methodologies. Working alongside product managers, researchers, and engineering teams, I led the design workstream from discovery through delivery, creating a modern, web-based platform that improved usability, reduced learning curve, and enabled mine operators to monitor efficiency, productivity, machine health, and miner safety from anywhere on various devices.

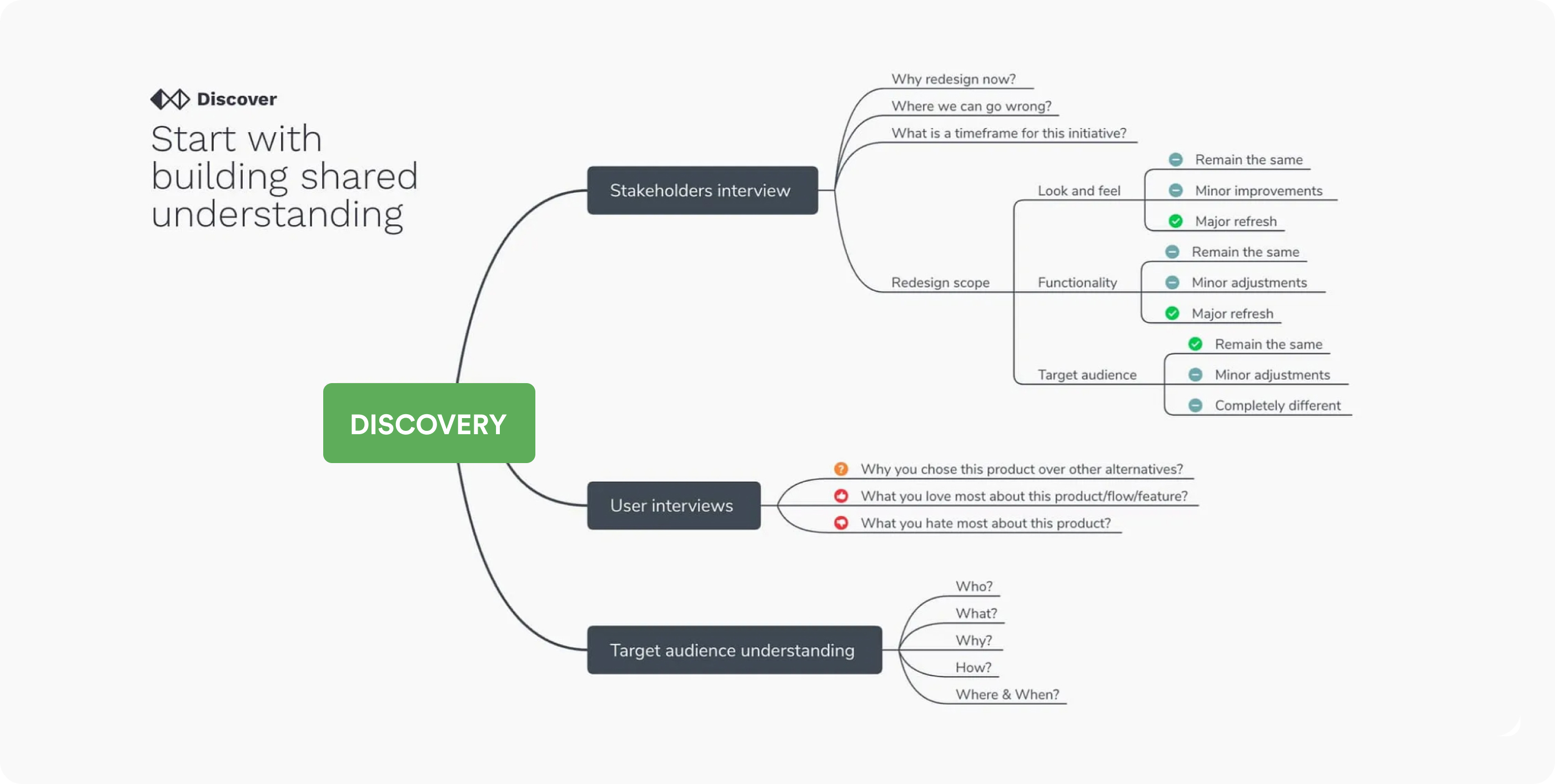

Newtrax leadership recognized that the legacy platform's profound usability issues and steep learning curve were damaging user/client relationships, with mine operators abandoning the software out of frustration. The digital transformation initiative aimed to modernize the platform using next-generation web technologies and user-centric methodologies. Key business objectives included:

We benchmarked mining operations software from leading competitors and modern web platforms to inform a competitive, user-centric mining platform UX. Key insights revealed that successful mining software platforms prioritize usability, real-time monitoring, and web-based access—enabling mine operators to monitor operations from anywhere without desktop installation. We adapted these patterns to Newtrax's mining ecosystem, creating a modernized web platform that matched competitor standards while maintaining Newtrax's safety-first approach and regulatory compliance.

Interviews with 28 mine operators and control room managers revealed consistent patterns around platform frustration:

These insights shaped our approach: creating a modern, web-based platform that is easy to use, includes safety features, enables real-time progress tracking, and works on various devices without desktop installation.

We redesigned Newtrax's legacy mining platform into a modern, web-based solution using next-generation web technologies and user-centric methodologies. The new platform eliminates desktop installation requirements, enables access from anywhere on various devices, and provides intuitive interfaces for monitoring efficiency, productivity, machine health, and miner safety. The transformation reduces learning curve, includes comprehensive safety tools, enables real-time progress tracking, and works seamlessly across devices—transforming Newtrax from a lagging legacy platform into a competitive, modern mining operations solution.

Design comprehensive safety tools and features for monitoring miner safety underground in real-time. The platform provides visibility into miner location, environmental conditions, and safety alerts—enabling control room operators to monitor and respond to safety issues quickly.

Enable mine operators to track work progress in real-time with intuitive dashboards and visualizations. The platform provides real-time updates on production, efficiency, and productivity metrics—helping control room operators monitor operations and make data-driven decisions.

Eliminate desktop installation requirements by providing web-based access from anywhere on various devices. The platform works seamlessly across desktop, tablet, and mobile devices—enabling mine operators to monitor operations from the control room, office, or on the go without installation barriers.

Design an easy-to-use and understand interface that reduces learning curve and frustration. Clear navigation, helpful documentation, and contextual guidance enable mine operators to adopt and use the platform confidently—improving user/client relationships and reducing abandonment.

To extend the value of Newtrax's platform transformation beyond surface-level design, we modernized the underlying mining platform architecture—improving performance, scalability, and user experience across all mining operations features. The platform modernization introduced faster load times, improved responsiveness, and enhanced reliability—enabling mine operators to monitor operations quickly and reliably without delays or errors.

The platform modernization introduced comprehensive safety monitoring, real-time progress tracking, and intelligent data visualization tools—helping mine operators discover insights, complete monitoring tasks, and make data-driven decisions without installation barriers. By combining web-based access, intuitive user experience, improved safety tools, and modern platform infrastructure, Newtrax's platform transformation transformed from a design update into a comprehensive mining operations modernization that positioned Newtrax as competitive with leading mining software providers.

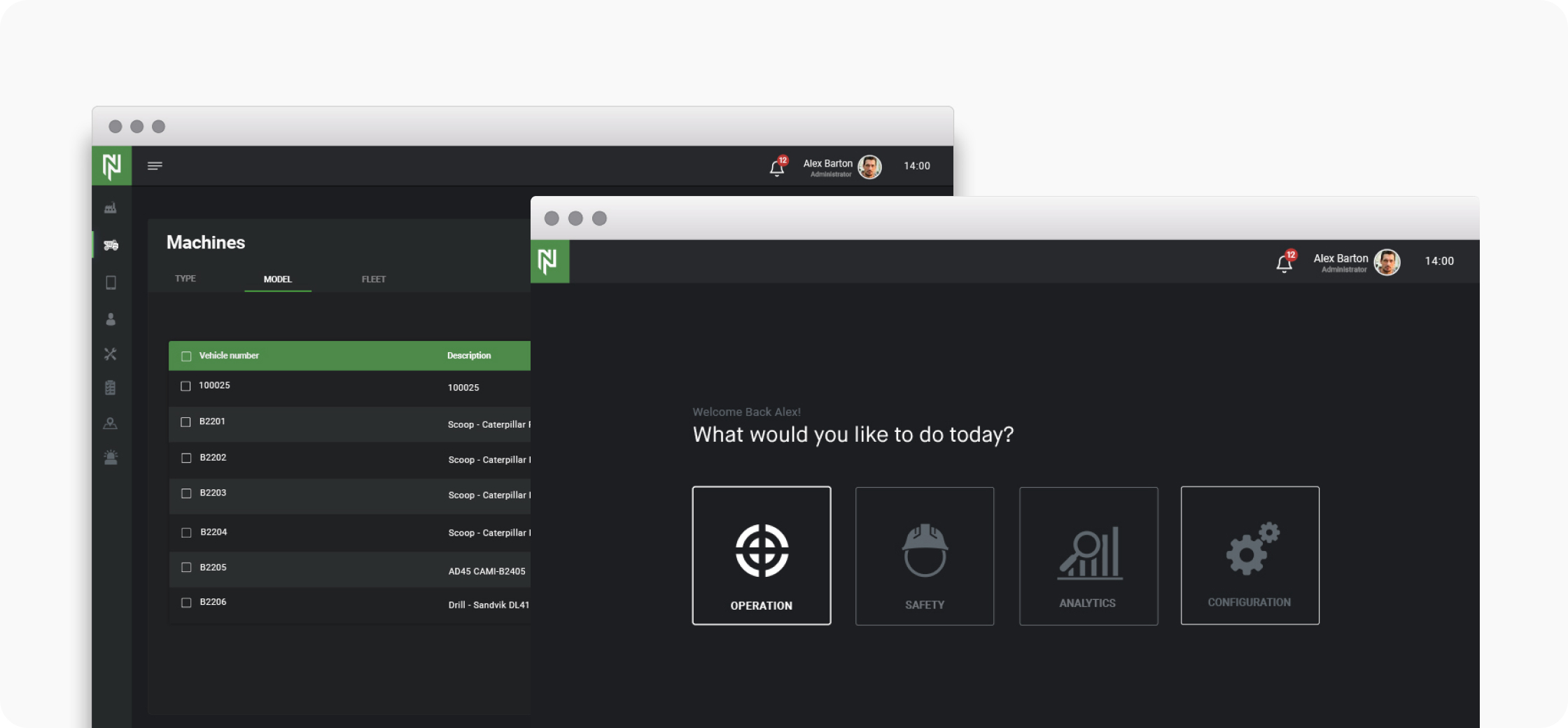

Mining operations dashboard interface for monitoring efficiency, productivity, machine health, and miner safety with real-time data visualization.

Complete safety monitoring workflow showing miner location tracking, environmental conditions, and real-time safety alerts for control room operators.

The Newtrax platform transformation successfully modernized the mining operations software—successfully bridging legacy platform constraints with modern web usability and positioning Newtrax as competitive in the mining software landscape.

Measured Outcomes:

The success of Newtrax's platform transformation demonstrated that mining software could be modernized — not through maintaining legacy constraints, but through smarter, user-centered web technologies that enable access from anywhere on various devices.

Through this initiative, we learned that modernizing mining software goes beyond feature parity. It requires usability, accessibility, and web-based flexibility. By aligning product, design, and engineering around a shared goal of user-centricity, we simplified workflows, reduced learning curve, and increased adoption. Clear navigation, helpful documentation, and web-based access proved essential in turning a complex legacy platform into an intuitive, user-friendly mining operations solution.

In mining software, even small design changes can have major implications for user adoption. During testing, we learned that complex navigation and unclear interfaces increased user frustration rather than productivity. The key was finding a balance — making the platform powerful without being overwhelming. Clear navigation, helpful documentation, and contextual guidance became essential in creating a sense of capability rather than confusion.

Working with mine operators meant understanding their need for flexibility and access from anywhere. Desktop installation requirements often limited adoption, forcing operators to work from fixed locations. Our success depended on designing a web-based platform that worked seamlessly across devices — enabling mine operators to monitor operations from the control room, office, or on the go without installation barriers. This web-based approach significantly improved platform adoption and user/client relationships.

Mining operations require comprehensive safety monitoring and real-time progress tracking to ensure efficiency, productivity, and miner safety. We designed safety tools and features that enabled control room operators to monitor miner location, environmental conditions, and safety alerts in real-time—transforming monitoring from reactive to proactive. Real-time progress tracking enabled mine operators to make data-driven decisions quickly—proving that safety and productivity features are as important as usability in driving mining operations success.

Thanks to cross‑functional partners across product, research, engineering and operations.

Mentored 4 junior designers on accessibility testing and user research, perfecting their visual design craft and shaping them into confident contributors to future secure UX projects.

There was a profound usability issue with the legacy platform that the majority of current users today have hard time using. The learning curve and lack of documentation ressources make it difficult for the mine operators to adopt the software and they stop using it out of frustration. Also, users today also prefer a more modern web based platform as they can utilize it's tools no matter where they find themselves and on various devices. While competitors are working on increasing usability and user experience in their software offerings, Newtrax has fallen behing for several years. In order to improve user/client relationships, a complete digital transofrmation of the lgeacy platform was needed, based on a next generation web software technologies and user-centric methodologies.

Who are the users?: The primary users are the mine operators that work daily above ground in the control room. These are the users that will use the tools to monitor efficiency, productivity, machine health and miner safety underground.

Advancing hard rock mining technology in designing a next generation enterprise platform with the best data sets to train AI and to allow for greater tracking of machines productivity and miner saftey.

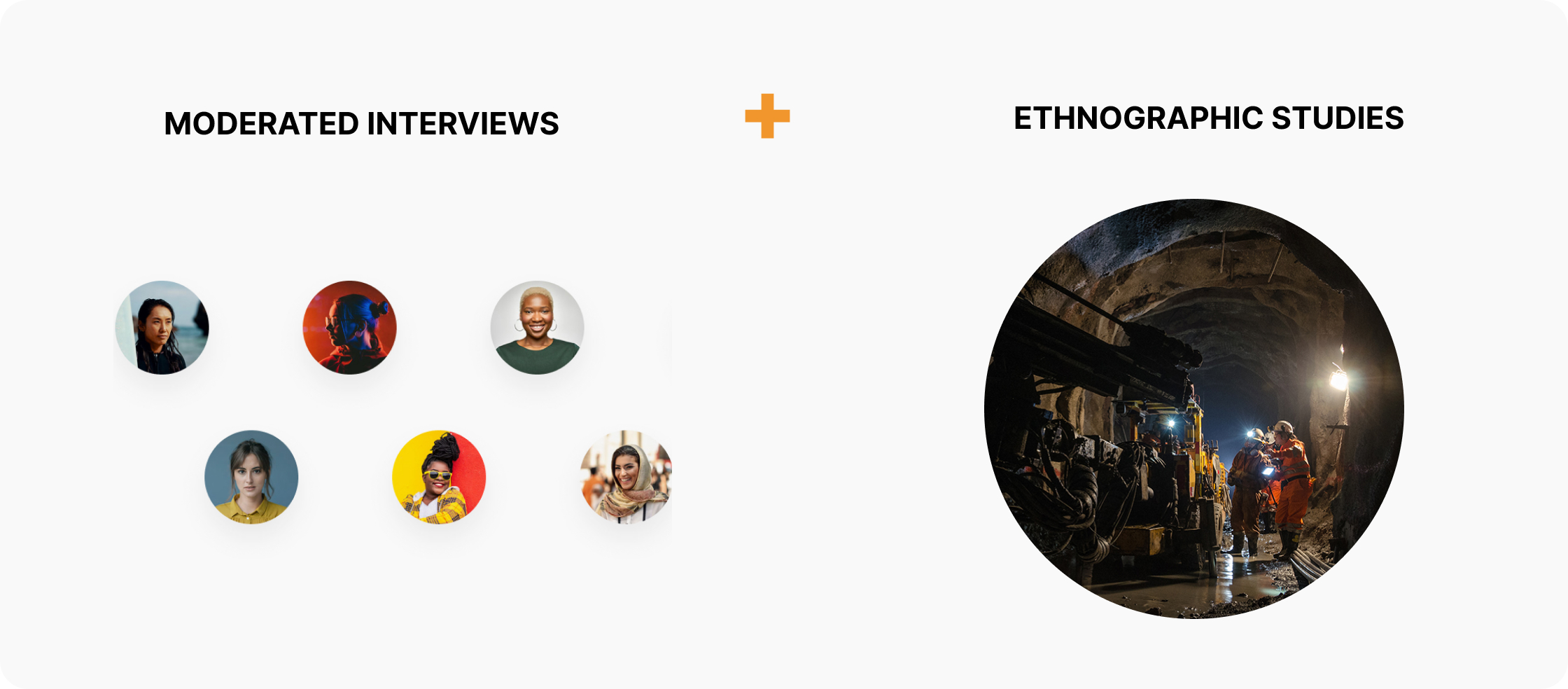

To further understand the frustrations and needs of the users, Newtrax sent me to various mines to observe and conduct ethnographic studies within the user's work enviroment. I visited mines in Brazil, the Unites States, Chile and Australia.

Moderated Interviews: I interviewed mine operators and mine managers from various countries to understand their frustrations and needs with the current product. The aim was to uncover issues causing frustration and determine how to improve their work experience and the relationship between operators, managers and miners.

Ethnographic Studies: I visted various mine sites to immerse myself in the users' real work settings, engaging with different user types such as mine managers, operators, supervisors, and miners. Spending weeks actively participating in their tasks using the legacy software, I directly experienced the frustrations users face daily. Throughout my mine visits, I gathered and analyzed field notes, later presenting these findings to the team.

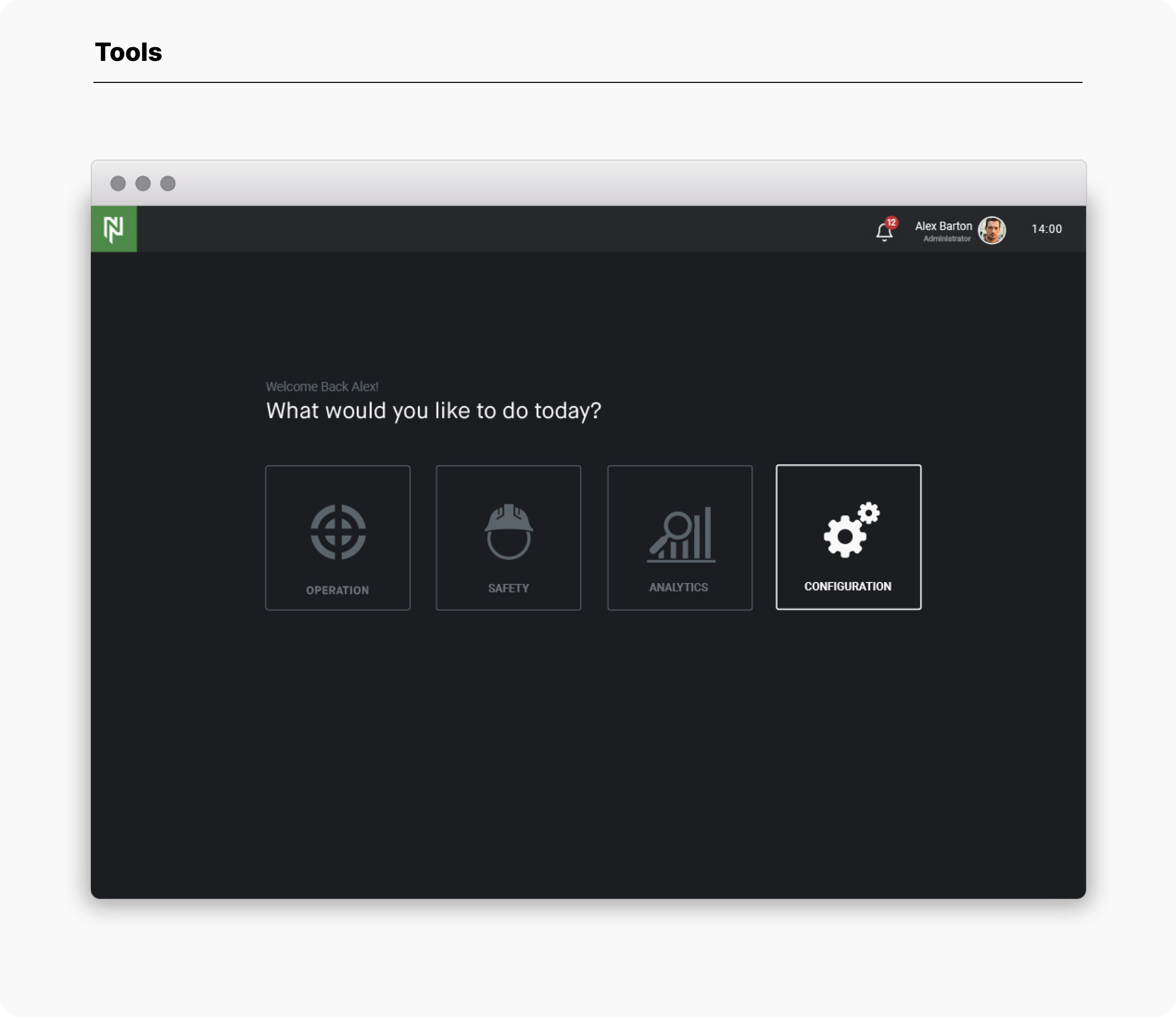

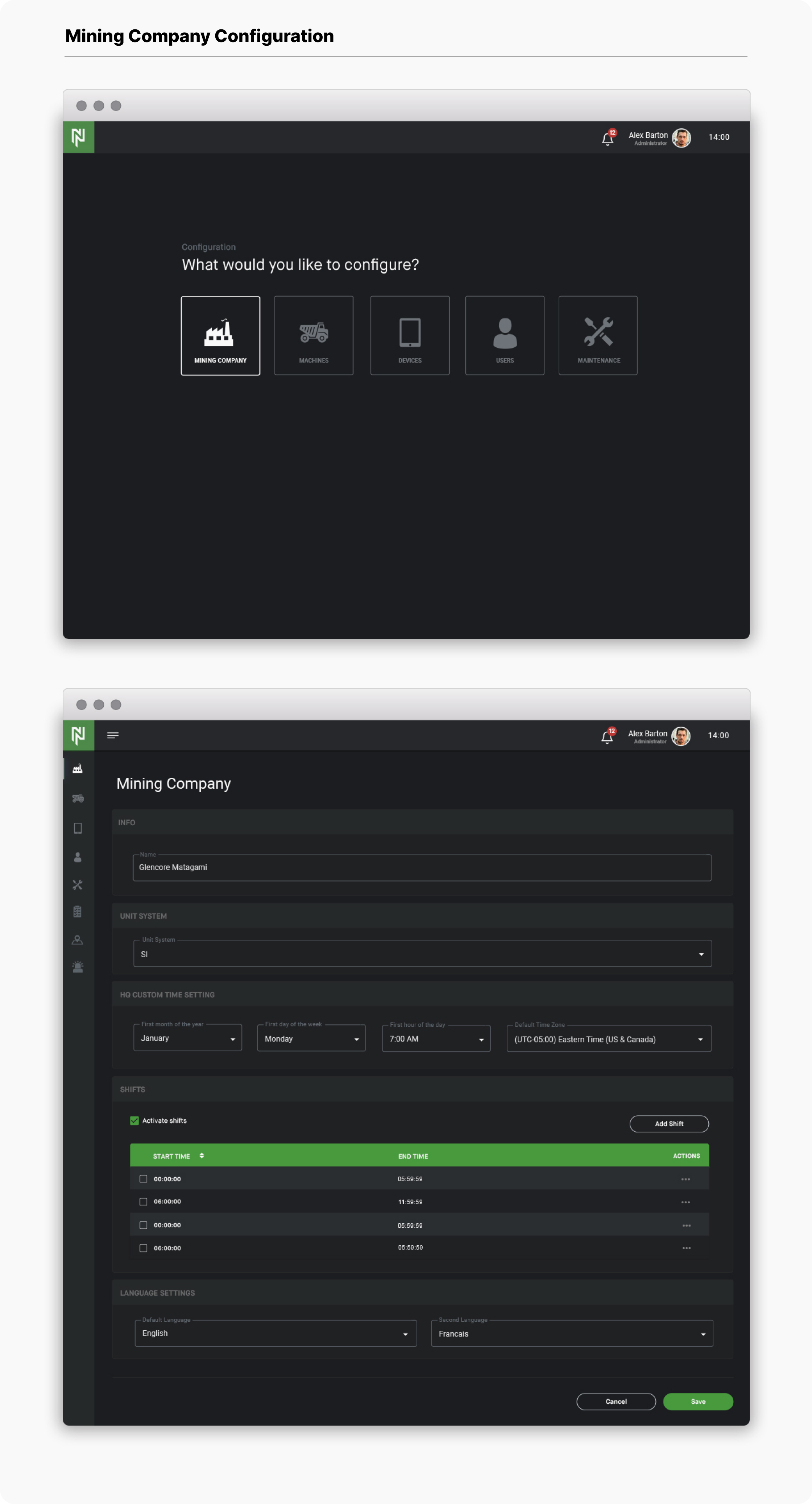

Presenting my findings to the team and stakeholders, I realized the issues stemmed from the old platform's development logic, neglecting user experience and flooding screens with information. Users, often without high education levels, struggled with data overload, particularly in South American countries. The design approach needed rethinking, especially considering that mine operators spend over 8 hours a day staring at screens, leading us to opt for a dark theme to reduce eye strain. We removed obsolete features, added modern tools, and addressed a crucial need for monitoring miners' environments with the Ventilation on Demand system. This system automates fan activation based on gas detection, improving safety and ease of use, facilitated by a mobile app for control underground.

There are thousands of hard rock mine sites around the world that lack proper safety and security systems to protect their workers. Adding to this, the lack of tracking, in real time, of underground activities, it becomes obvious that there is a significant need for more cutting edge techology and software to facilitate the overall mine management.

A better experience for mine managers and operators also means bringing in safety and prevention to the underground workers. With the ability to see everything that is going on in real time underground, this is a game changer in the mining industry.

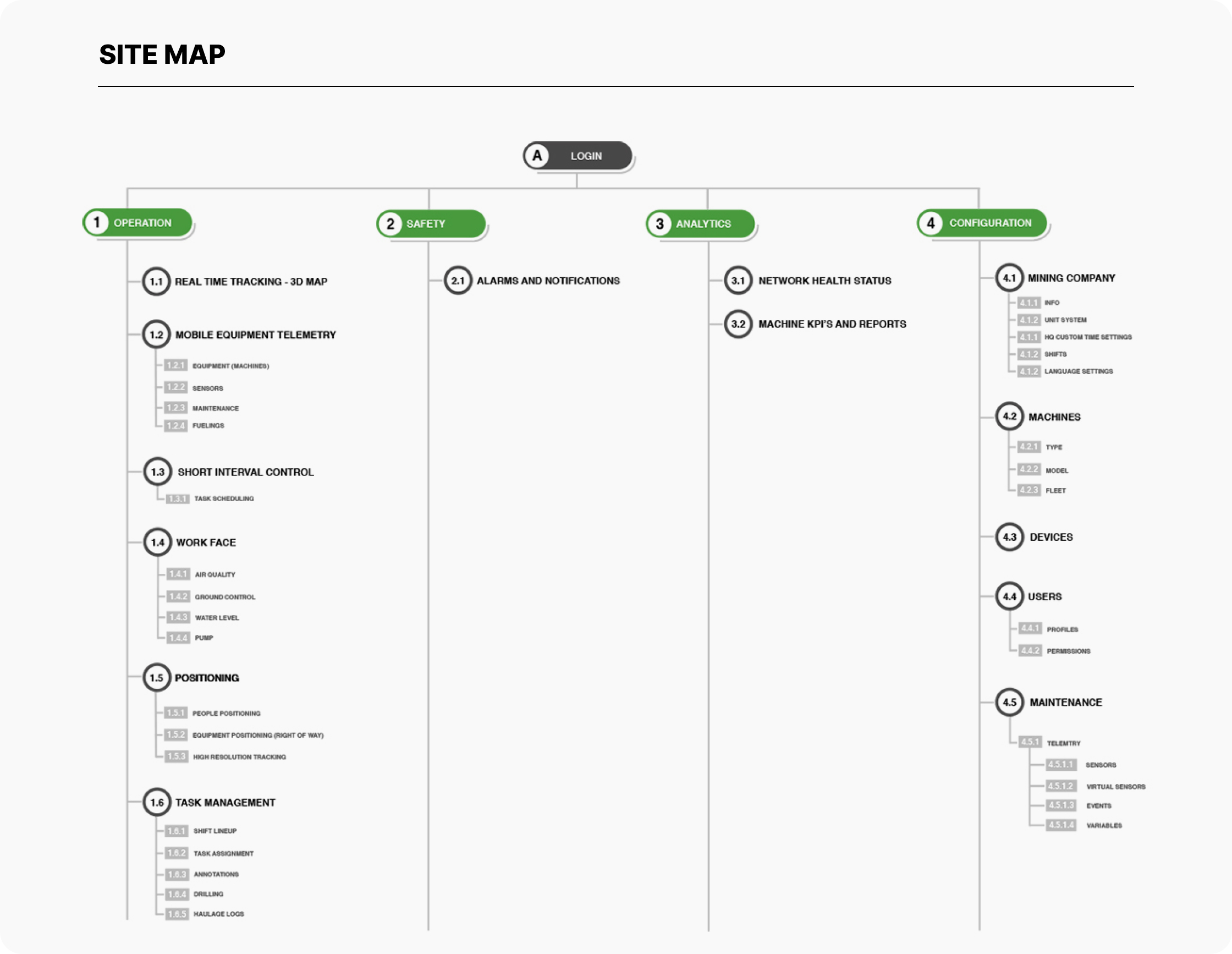

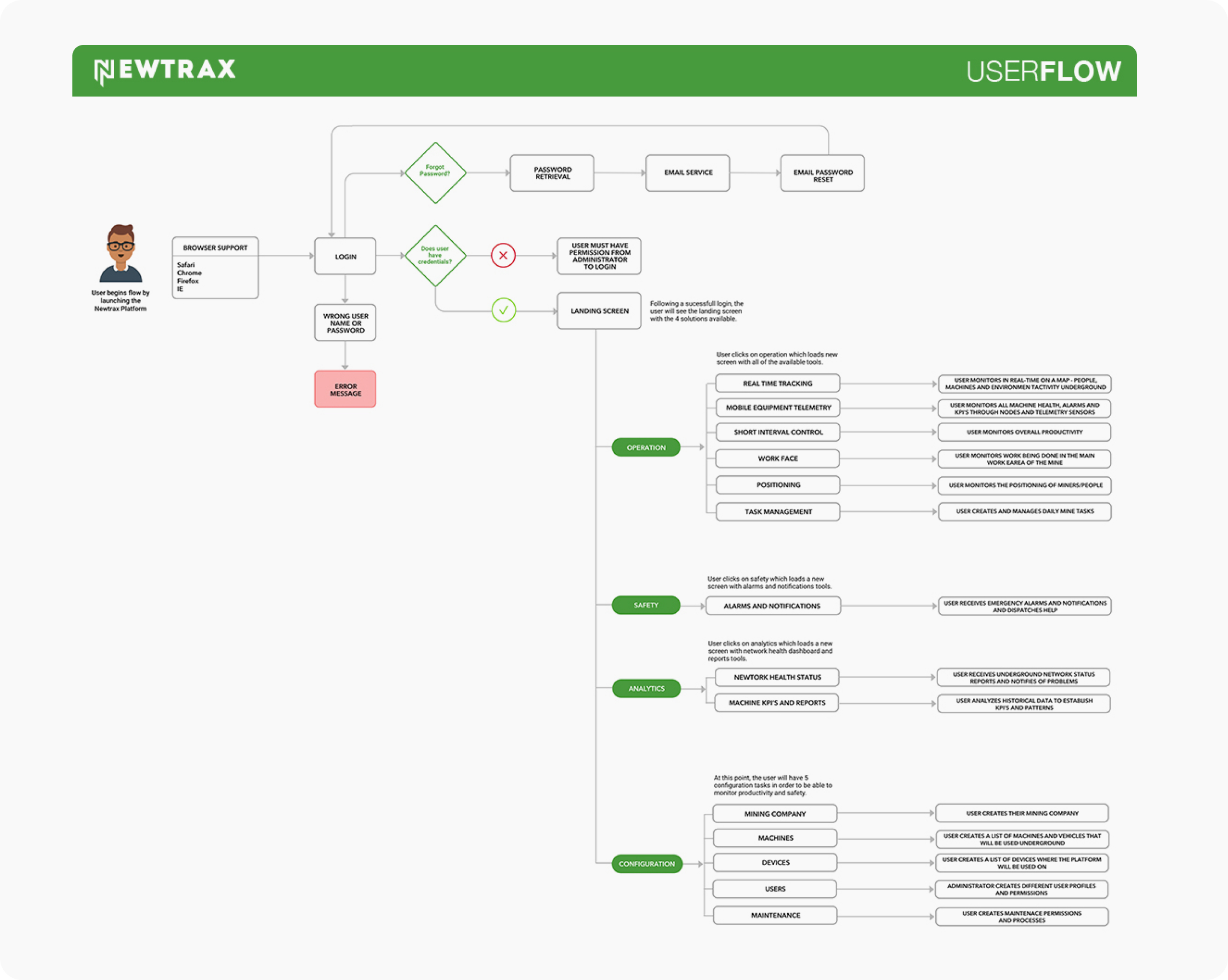

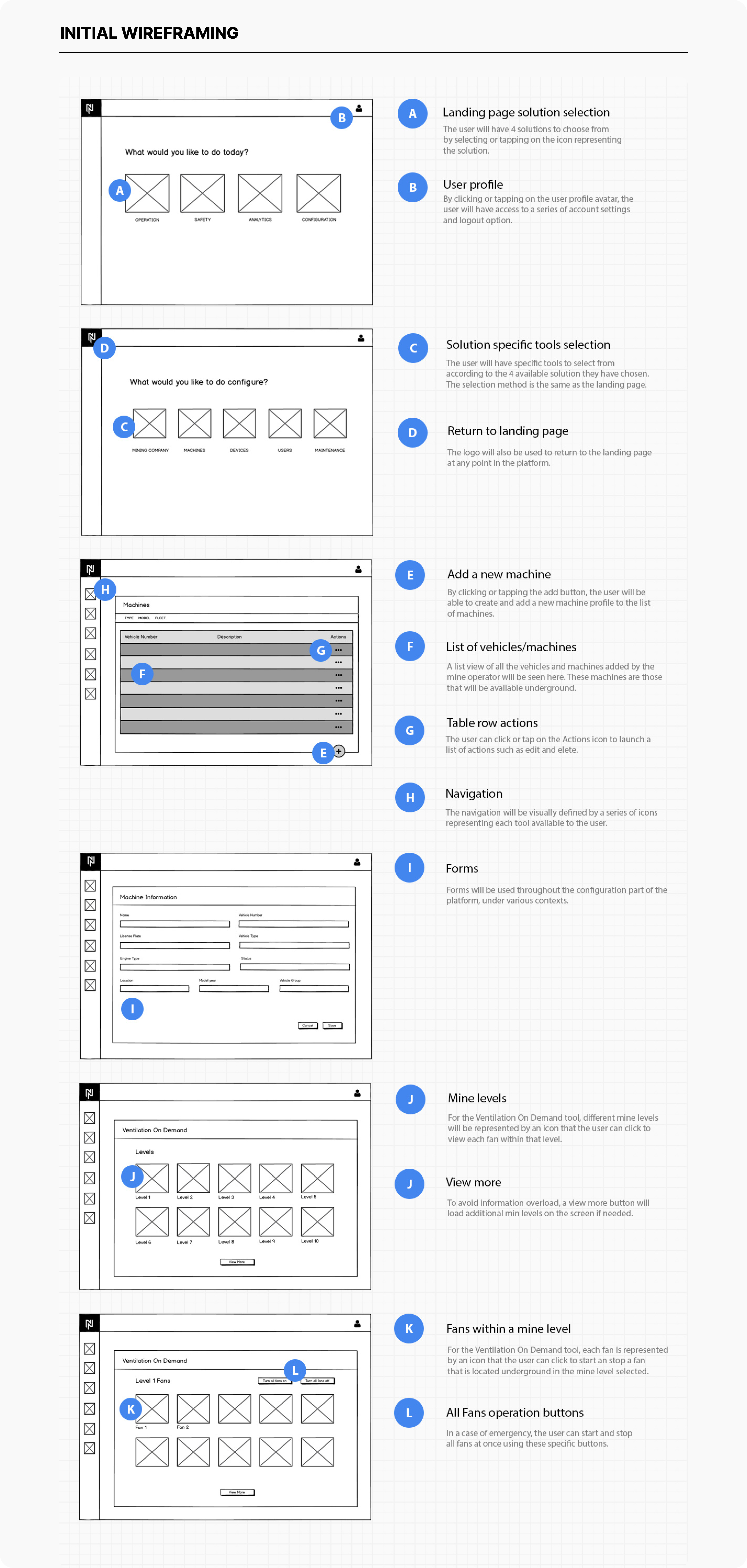

Design began with the set of tools and features. The goal was to categorize each tool sets in specific operational categories.

The 3D map visualizer is built with the overall purpose to monitor the location of people, machines, and network infrastructure in real-time and unlock location-based analytics. The implementation of the map for each mine was developped using multiple network nodes in mapping out the different tunnels and levels deep. I worked closely with engineers to make sure that the detection sensors would communicate via the underground network straight to the Map visualizer in the platform. This enabled real-time location tracking.

As a companion to the Web platform, the mobile app was desigend to provide underground mine supervisors a quick and easy tool to launch, pause or abort a tasks, track the amount of time allocated to the task and also launch underground ventilation systems from the mobile device.

Along with enginners, the Tag Board was designed to provide a portable tool that allows an overview of all the workers underground during a given shift. Each tag is associated to a cap lamp where the tracking sensor is embedded into.

Figuring out which employee is asigned to a vehicle for their entrie shift was a problem. By leveraging the same concept behind the cap lamp design, a driver of a vehicle can be tracked also by creating an association between the driver and the specific vehicle.

The platform was a huge success post launch as it filled an immense gap in operations managament and easye of use. The addition of health and safety features, machine health through telemetry, and task management relieved many of the users previous frustrations.